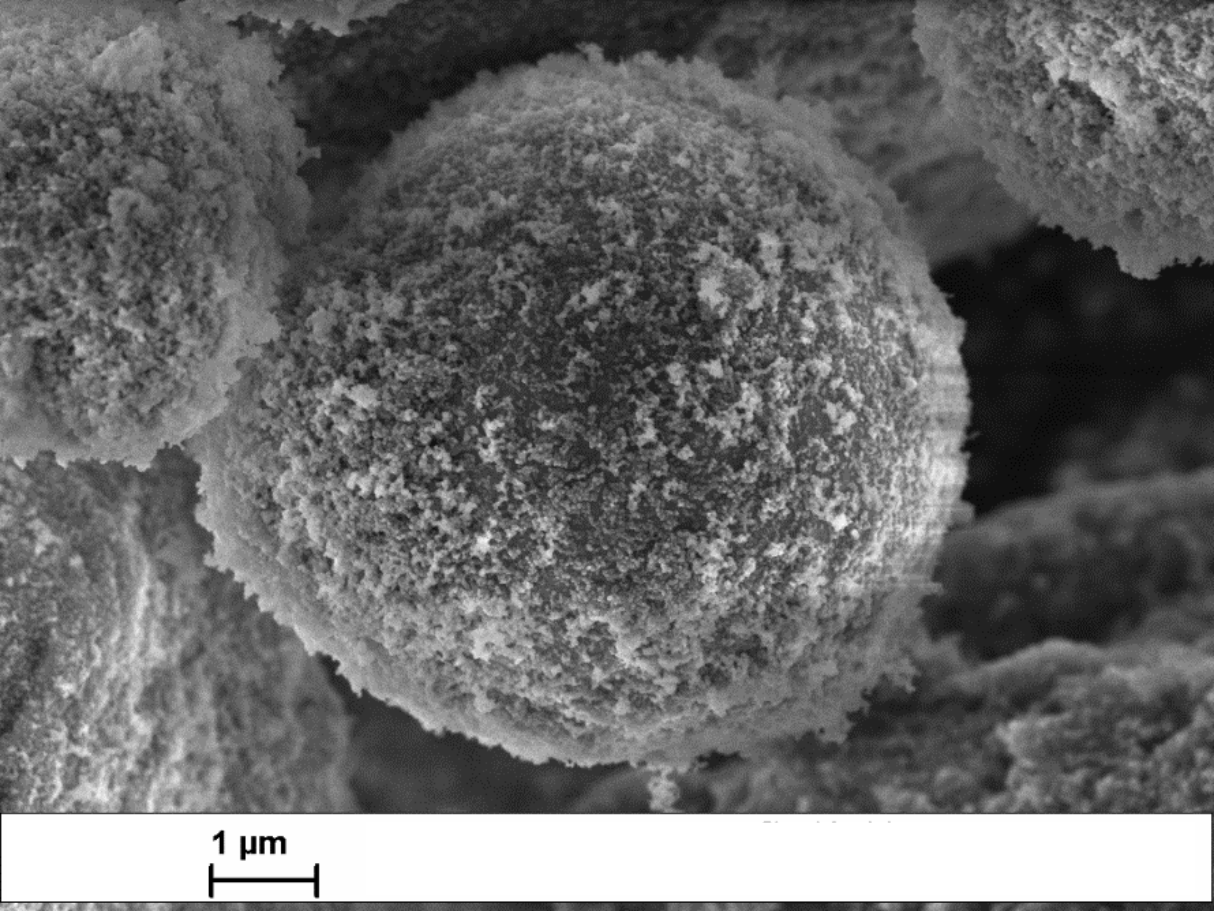

SiC and Si nanopowders in industrial quantity

Patented nanometric powders

Silicon carbide nanopowders for elastomers, polymers, ceramics, metals and Silicon nanopowders for increasing the energy density of the anode in Lithium-ion batteries.

Industrial production of nanopowders

thanks to Laser Pyrolysis

Nanomakers is a company who develops, produces and sells patented silicon based nanometric powders in industrial quantity for disruptive reinforcement of materials (elastomers, polymers, ceramics, metals) and the improvement of energy density of the anode in Lithium-ion batteries.

Discovered by MIT in 1980 and taken over by the CEA in 1985, the LASER PYROLYSIS allows the production of high purity nanopowders.

After 25 years of development at the CEA, the technology (unique in the world), licensed and used by Nanomakers since 2010 and allows it to produce nanoparticles at a industrial scale since 2012.

Innovative nanomaterials

in use in various applications

The silicon carbide (SiC) and Silicon (Si) nanopowders produced by Nanomakers increase significantly the performances of industrial materials.

The nano SiC can increase the mechanical, thermal and chemical resistances of materials such as elastomers, polymers, ceramics, metals, composites...

The Si or carbon coated Si can improve the energy density of Lithium-ion batteries.

Innovative markets and applications

for nanomaterials

The Silicon Carbide (SiC) nanopowders are compatible with a wide range of materials. This makes it a good material that all industries can use to reinforce existing materials or develop new ones.

The same goes for Silicon or Silicon coated nanopowders (Si/SiΩC).

A disruptive improvement

thanks to nanomaterials

The industry involving materials is concerned with the disruptive improvement of its products and the implementation of solutions promoting sustainable development. Each of the major markets affected by the use of nanomaterials will find solutions for:

Optimizing existing materials and developing future materials

Preserve natural resources and be part of a dynamic of sustainable development

Innovative development projects

supported by partners

The development projects that Nanomakers participates in are many and various. Thanks to the support of our partners, we are working to make these innovative projects a reality, which can bring real progress to the targeted markets.

For example, Nanomakers has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 880701.